Embodied Carbon in the architectural glass and aluminum industry

December 15, 2021

On April 22nd, 2021, president Biden announced a new target for the United States to achieve a 50 – 52 percent from 2005 levels in economy-wide net greenhouse pollution in 2030. As members of the architectural aluminum and glass industry, we must ask what our role will be in reaching the goals set by the president.

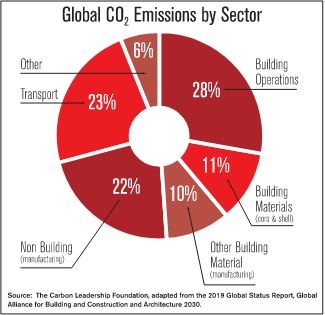

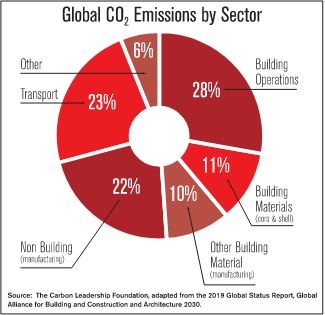

According to Architecture 2030, an organization focused on transforming the built environment, buildings generate nearly 40% of annual global CO2 emissions. Those building operations are responsible for 28% annually, while materials and construction are responsible for an additional 11% annually.

That’s where embodied carbon comes in. According to the Carbon Leadership Forum (CLF), embodied carbon refers to GHG emissions that come from manufacturing, transporting, installing, maintaining, and disposing of building materials in the building industry. According to the CLF, building materials account for 11% of total global CO2 emissions.

Embodied carbon emissions are generated by the manufacturing, transportation, installation, maintenance, and disposal of construction materials used in buildings, roads, and other infrastructure. Upfront embodied carbon (also known as upfront carbon) refers to the greenhouse gas emissions released before a building or infrastructure starts being used, which are largely from manufacturing impacts.

Both glass and aluminum manufacturing processes rely on high-temperature heat that has not been fully replaced by cleaner energy sources. For architectural glass, most of the em-bodied carbon originates from converting sand and clay to glass. Approximately 75%

of the embodied carbon in an IGU occurs as a result of ?at glass manufacturing. Aluminum production is also energy-intensive, though in the U.S. about 70% of electricity consumed in aluminum smelting facilities comes from hydroelectric sources, according to the Aluminum Association, which notes this helps reduce the environmental impact of the process.

As members of the architectural aluminum and glass industry, we should review each component of our supply chains to find solutions that will contribute to the goals set by President Biden. While the processing of base materials is a major contributor to CO2 emissions, we must also review where our materials are sourced and how far they must travel to the project site.

According to Architecture 2030, an organization focused on transforming the built environment, buildings generate nearly 40% of annual global CO2 emissions. Those building operations are responsible for 28% annually, while materials and construction are responsible for an additional 11% annually.

That’s where embodied carbon comes in. According to the Carbon Leadership Forum (CLF), embodied carbon refers to GHG emissions that come from manufacturing, transporting, installing, maintaining, and disposing of building materials in the building industry. According to the CLF, building materials account for 11% of total global CO2 emissions.

Embodied carbon emissions are generated by the manufacturing, transportation, installation, maintenance, and disposal of construction materials used in buildings, roads, and other infrastructure. Upfront embodied carbon (also known as upfront carbon) refers to the greenhouse gas emissions released before a building or infrastructure starts being used, which are largely from manufacturing impacts.

Both glass and aluminum manufacturing processes rely on high-temperature heat that has not been fully replaced by cleaner energy sources. For architectural glass, most of the em-bodied carbon originates from converting sand and clay to glass. Approximately 75%

of the embodied carbon in an IGU occurs as a result of ?at glass manufacturing. Aluminum production is also energy-intensive, though in the U.S. about 70% of electricity consumed in aluminum smelting facilities comes from hydroelectric sources, according to the Aluminum Association, which notes this helps reduce the environmental impact of the process.

As members of the architectural aluminum and glass industry, we should review each component of our supply chains to find solutions that will contribute to the goals set by President Biden. While the processing of base materials is a major contributor to CO2 emissions, we must also review where our materials are sourced and how far they must travel to the project site.